8.7/10kV-290/500kV XLPE insulated with or without Optical fiber Submarine cable

Application:

This submarine cable is used for connecting between land islands, crossing rivers or harbors, connecting drilling platforms from land or connecting drilling platforms to each other, etc. Single-core submarine cables are often used for large island connections for permanent populations, large capacity transmission across rivers and straits. Three-core submarine cables are often used for island power supply and offshore wind turbines.

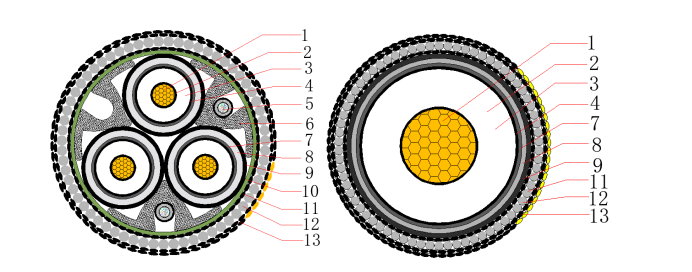

Construction:

1. Conductor - Plain annealed class 2 circular compacted conductor copper conductor

2. Conductor screen – Semi-conductive compound

3. Insulation - Cross linked polyethylene (XLPE)

4. Insulation screen - Semi-conductive compound

5. Communication unit - Optical fiber cable

6. Filler - Fan-shaped filling

7. Watertight Bedding - Semi-conducting water swellable tape

8. Metal screen - Lead alloy sheath

9. Inner sheath - Semi-conductive PE sheath

10. Binder tape - Polymeric tape

11 Inner serving - Polypropylene yarn

12 Armor - Galvanized steel wire

13. Outer serving- Polypropylene yarn

Cross Section:

1 core; 50~3500mm2

3 core; 50~800mm2

Temperature characteristics:

Conductor operating temperature: -15℃~90℃

Min. temperatrue laying condition: 0℃

Conductor emergency operating temperature: 105℃

Conductor short-circuit operating temperature (5s): 250℃

Standard:

Cable design: JB/T11167、IEC63026

Conductor: GB/T 3956, IEC 60228

Our cables are generally packed in wooden drums, steel-wooden drums, or steel drums. For cables of shorter lengths or smaller sizes, coil packaging on pallets is also available.

Beijing National Stadium

China Pavilion at Expo 2010 Shanghai China

Shanghai Jin Mao Tower

Lilyvale Solar Farm in Australia

Oyu Tolgoi Project in Mongolia

Shanghai Pudong International Airport